For a long time, to improve the survival rate of the battlefield and reduce the casualties of soldiers, the U.S. military has begun to use a variety of individual bulletproof equipment. From the small-scale trial of M9152 in the Korean War to the large-scale distribution of M1955 and M1969 in the Vietnam War, these so-called bulletproof vests can not resist the direct attack of bullets. At best, they can only resist the fragments of grenades Bullet bouncing or non-direct hit shell fragment attack.

It was not until the emergence of Kevlar material in the 1980s that the later PASGT vest had certain bulletproof performance, but it was only limited to resisting the penetration of projectile equivalent to 9mm caliber pistol bullet at a certain speed and angle. Since the birth of rifles and bullets, the performance of guns has been far beyond the development of protective equipment. Many bullets are difficult to resist even with a certain thickness of steel plate. In addition, the load that soldiers can bear is limited. Too heavy bulletproof equipment will only consume soldiers' physical and mechanical ability, which is meaningless to the improvement of battlefield protection.

For obtaining a better bulletproof effect, lightweight and strong bulletproof materials have always been the goal of human exploration. After PASGT OTV became the first bulletproof vest with real bulletproof performance officially installed by the U.S. military, and the reason for obtaining this capability is the emergence of SAPI - small arms protective insert plug-in light weapons protective plate. OTV uses a hard silicon carbide ceramic plate to obtain higher protection ability on the basis that soft Kevlar materials can only achieve limited protection.

According to the requirements of the military, a standard size SAPI must be able to effectively resist the impact of 7.62mm M80 projectile flying at the speed of 841m per second, and each SAPI must be able to withstand three such impacts. This means that the OTV vest equipped with SAPI can resist 7.62 fired by AK47 rifle × The attack of 39mm projectile is a qualitative improvement for individual protection!

In 2003, a large number of individual bulletproof vests dominated by OTV have distributed to every U.S. soldier deployed on the front line. This also greatly reduced the probability of soldiers being directly hit by bullets and dying in the two wars. However, the opponents in the war on terrorism are not a mob. Their weapons are not only old AK47 rifles. Snipers use a large number of Russian-made SVD sniper rifles with a caliber of 7.62 × 54mm, the penetration of projectile is stronger.

In addition, the anti-U.S. forces began to use armor-piercing bombs for targeted attacks according to the characteristics of the U.S. military's strong protection ability, so the U.S. military began to use the boron carbide ESAPI enhanced small arms protective insert produced by Ceradyne, BAE Systems, and ArmorWorks in May 2005, This ESAPI can resist the attack equivalent to. 30-06 caliber M2 steel core or tungsten core armor-piercing projectile, but the cost of ESAPI is high, and the price of each piece is up to $600.

In the following years, the threats faced by the U.S. ground forces did not decrease, so the U.S. Army put forward the concept of the next generation of the protective plate, namely XSAPI. The army requires this new generation of the hard protective plate to be more flexible, convenient, and systematic, with a larger protective area and no increase in weight. Because of the end of the war on terrorism, XSAPI did not officially appear in the U.S. military sequence, but the design of XSAPI did not stop. Once the U.S. military faces new threats again, this next-generation light weapons protection board will be quickly distributed and put into use.

At first, the performance of the SAPI board used in the bulletproof vest represented by OTV was not rated by NIJ, that is, the National Institute of justice because it was designed at the request of the military and tested according to the military standards. The standards formulated by the military are not equivalent to the NIJ test standards, but after SAPI achieved a series of successes on the battlefield, Civil and law enforcement markets also particularly favor it, so NIJ has also conducted a series of standard evaluations. Generally speaking, the standard SAPI plate has bulletproof performance above level III. The local fragmentation of the hard ceramic layer of the SAPI plate is used to offset the kinetic energy of the invading projectile, passivate the penetration of the projectile, and then use the buffer layer with a larger area of SAPI to diffuse the impact force, block the projectile fragments and minimize the possibility of fatal injury.

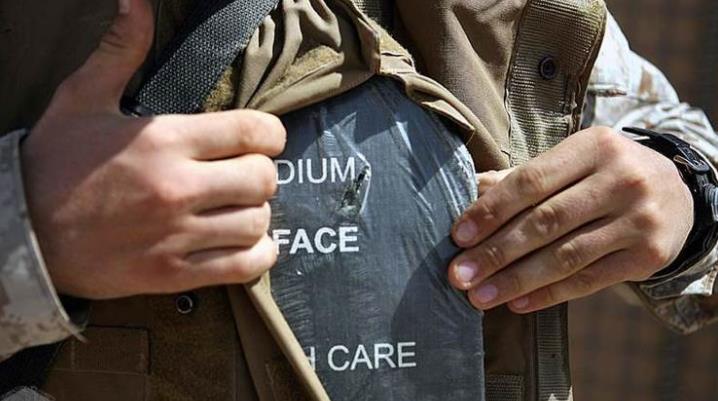

In other words, SAPI can not guarantee that the user will be unharmed, but can only ensure that the user will not suffer fatal damage. In many instances, SAPI can escape the disaster because of the use of SAPI, but the nonfatal secondary injury caused by the powerful force of projectile is very common. To reduce this kind of injury, the U.S. military generally requires a combination of soft and hard bulletproof vests, which is to use a hard SAPI board outside the soft protective layer, which can effectively reduce the occurrence of secondary damage.

OTV is the U.S. military’s first tactical vest with real bulletproof capabilities. It also benefits from the use of SAPI boards. Later, the U.S. military’s IOTV\MTV\IMTV\SPC\SPCS and other tactical bulletproof vests all use SAPI/ESAPI boards. Obtain sufficient bulletproof capabilities. In order to meet different needs, SAPI is designed into two types, front and side. Front and back chest use front and side ribs. In terms of appearance, SAPI's unique corner-cut trapezoid has become one of its iconic features. The side type SAPI uses less corner design and is smaller in size.